ROOF TRUSS

|

A truss is a rigid framework composed of beams or other structural elements arranged to distribute weight efficiently. In engineering, a truss consists of two-force members, meaning each member experiences force only at its two endpoints. While trusses can take various shapes, they are most commonly built using triangular units connected at joints called nodes, ensuring stability and strength. A roof truss serves as the primary support structure for a roof, bridging the space above a room while evenly distributing loads. Trusses are installed at regular intervals and connected by longitudinal members like purlins, enhancing the overall strength and integrity of the roofing system.

|

TYPES OF ROOF TRUSSES

In today’s world, safety is a top priority, making it essential to install the best roof truss type for your home. Roof trusses are designed to efficiently distribute external forces, ensuring stability and durability. These forces act mainly on the node areas, but the truss structure disperses them effectively.

Additionally, truss joints function as revolute joints, meaning they eliminate torsional forces while maintaining structural integrity. With various types of roof trusses available, here are some of the most popular options and their distinct features.

Additionally, truss joints function as revolute joints, meaning they eliminate torsional forces while maintaining structural integrity. With various types of roof trusses available, here are some of the most popular options and their distinct features.

|

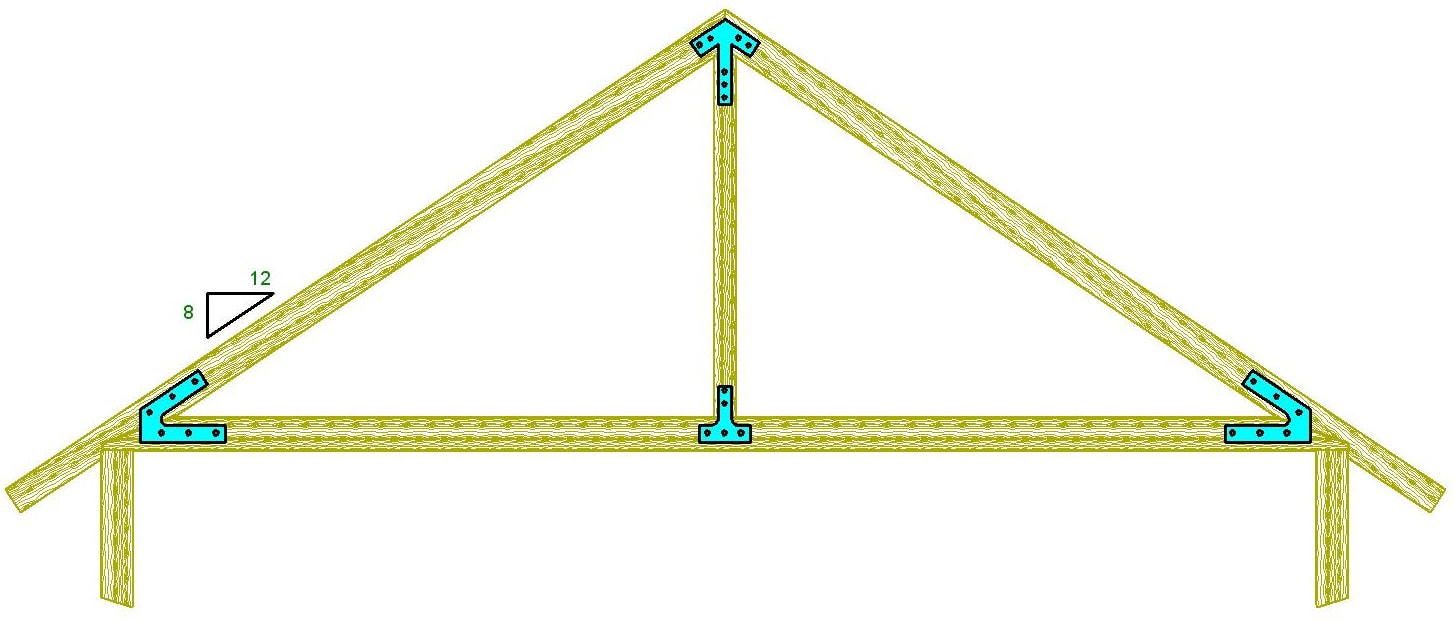

KING POST TRUSS

A king post truss features a vertical post extending from the tie beam to the apex of a triangular truss. The king post, under tension, connects the top and base of the truss, providing essential support. In some designs, the post is replaced with an iron rod, known as a king rod or king bolt, forming a king rod truss. Also referred to as a Latin truss, this design is ideal for spans up to 8 meters, making it a perfect choice for smaller homes and various residential structures. |

|

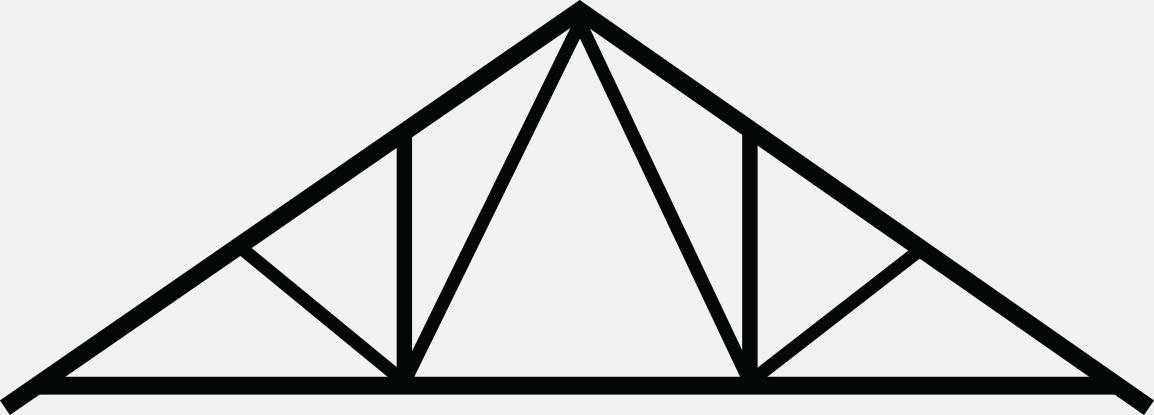

QUEEN POST TRUSS

A queen post truss is a structural system designed for longer spans compared to a king post truss. Instead of a single central post, it features two vertical tension members positioned about one-third of the way from each end of the truss. These uprights are connected at the top by a horizontal beam, with diagonal braces reinforcing the structure. Depending on the span length, the central square between the vertical posts may remain unbraced or include one or two diagonal braces for additional rigidity. The diagonal braces can be arranged in a single diagonal pattern or an "X" formation for enhanced support. With an optimal span of around 10 meters, the queen post truss is a great choice for larger homes and extended spaces requiring durability and load distribution. |

|

PRATT TRUSS

The Pratt truss, invented in 1844 by Thomas and Caleb Pratt, is a widely used truss design featuring vertical compression members and diagonal tension members that slope downward toward the center of the span. This design is the opposite of the Howe truss, where diagonals slope upward toward the center. In a balanced loading condition, the interior diagonal members experience tension, while the vertical elements handle compression. If pure tension elements like eyebars are used for the diagonals, additional crossing elements near the center may be required to support concentrated live loads as they move across the structure. The Pratt truss can also be subdivided, forming Y- and K-shaped patterns for increased stability and weight distribution. Its efficient use of materials makes it a popular choice for bridges, buildings, and other large-span structures. |

|

HOWE TRUSS

The Howe truss was introduced by American architect William Howe and shares a similar structural design with the Pratt truss, but with a key difference in the orientation of the diagonal beams. In a Howe truss, the diagonal members slope toward the center, placing them under compression, while the vertical members experience tension. This is the opposite of the Pratt truss, where diagonal members are in tension and vertical members are in compression. Due to its strong load-bearing capacity, the Howe truss is widely used for bridges, roofs, and other large-span structures. It can cover spans ranging from 6 to 30 meters, making it a versatile and reliable choice for various engineering applications. |

|

FINK TRUSS AND FAN TRUSS

The Fink truss is a widely used truss design with web members forming a V-pattern that repeats multiple times, efficiently distributing loads to the supports. As the top chords slope downward from the center, the V-shaped sections become progressively smaller. The truss has two common variations: the Double Fink truss, which extends the V-pattern twice on either side, forming a double-W shape, and the Fan truss, where web members fan out from the bottom joints with added vertical supports. With a span capacity of 10 to 15 meters, the Fink truss is a strong, lightweight, and cost-effective solution for various structural applications. |

|

It can be used for spans from 20-30m. Commonly used for industrial buildings.

|

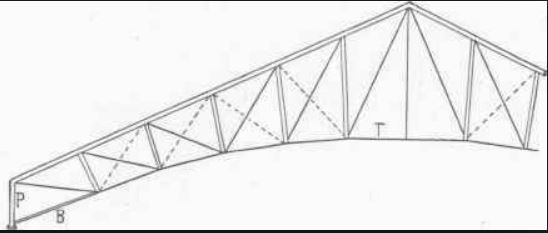

NORTH LIGHT ROOF TRUSS

When a floor span exceeds 15 meters, it becomes more economical to transition from a simple truss system to a wide-span lattice girder arrangement that supports trusses at right angles. To ensure proper lighting, roof lighting must replace or supplement side lighting, while ventilation should also be incorporated into the roof design. One of the oldest and most cost-effective methods for covering large areas is the North Light and Lattice Girder system, which consists of a series of trusses fixed to girders. In the Northern Hemisphere, the short vertical side of the truss is glazed and positioned to face north, maximizing natural light efficiency. |

|

QUADRANGULAR ROOF TRUSS

A quadrangular truss is a type of truss with parallel chords and a web member arrangement consisting of tension diagonals and compression verticals. It is commonly used in large structures such as auditoriums and railway sheds. This truss can be viewed as two trussed rafters stabilized by a central tie. A well-known example of this design is Madison Square Garden, the largest arena in New York. |

|

PARALLEL CHORD ROOF TRUSS

Commonly used in cathedral ceilings, the parallel chord roof truss features a sleek and functional design. It consists of two parallel chords reinforced by trusses in between, providing structural stability. Due to the need for steel bracing, its cost is higher than other truss types. Additionally, this truss helps reduce condensation and mold issues by creating a vapor barrier, improving indoor air quality. |

|

RAISED HEEL ROOF TRUSS

Raised-heel trusses are engineered wood trusses designed with an elevated heel where the bottom chord meets the perimeter wall plate, raising the top chord. This added height allows for increased insulation without compression, improving energy efficiency. Additionally, it helps reduce condensation and mold issues by creating a vapor barrier, enhancing indoor air quality. |

|

SCISSOR ROOF TRUSS

A scissors truss is a type of truss used in building construction, where the bottom chords cross each other and connect to the angled top chords at an intermediate point, resembling an open pair of scissors. This design is ideal for supporting pitched roofs while creating a sloped or raised ceiling, adding both structural integrity and aesthetic appeal. |

PARTS OF A ROOF TRUSS

|

Wanna know more about Roof Trusses? Check out HERE.